MINNEAPOLIS--(BUSINESS WIRE)--Industrial automation manufacturer Banner Engineering has introduced a new family of products that simplifies monitoring of equipment in factories and other industrial applications to enable predictive maintenance, reduce costs, and maximize uptime.

These new products include two customizable and scalable systems that enable users to immediately begin capturing data from sensors by attaching them to existing manufacturing assets, such as conveyor systems, industrial fans, pumps, electric motors, compressed air systems, and dust-collection units. Banner Monitoring Solutions keep assets operating efficiently, prevent costly unplanned downtime, and help ensure machines deliver consistent, high-quality output.

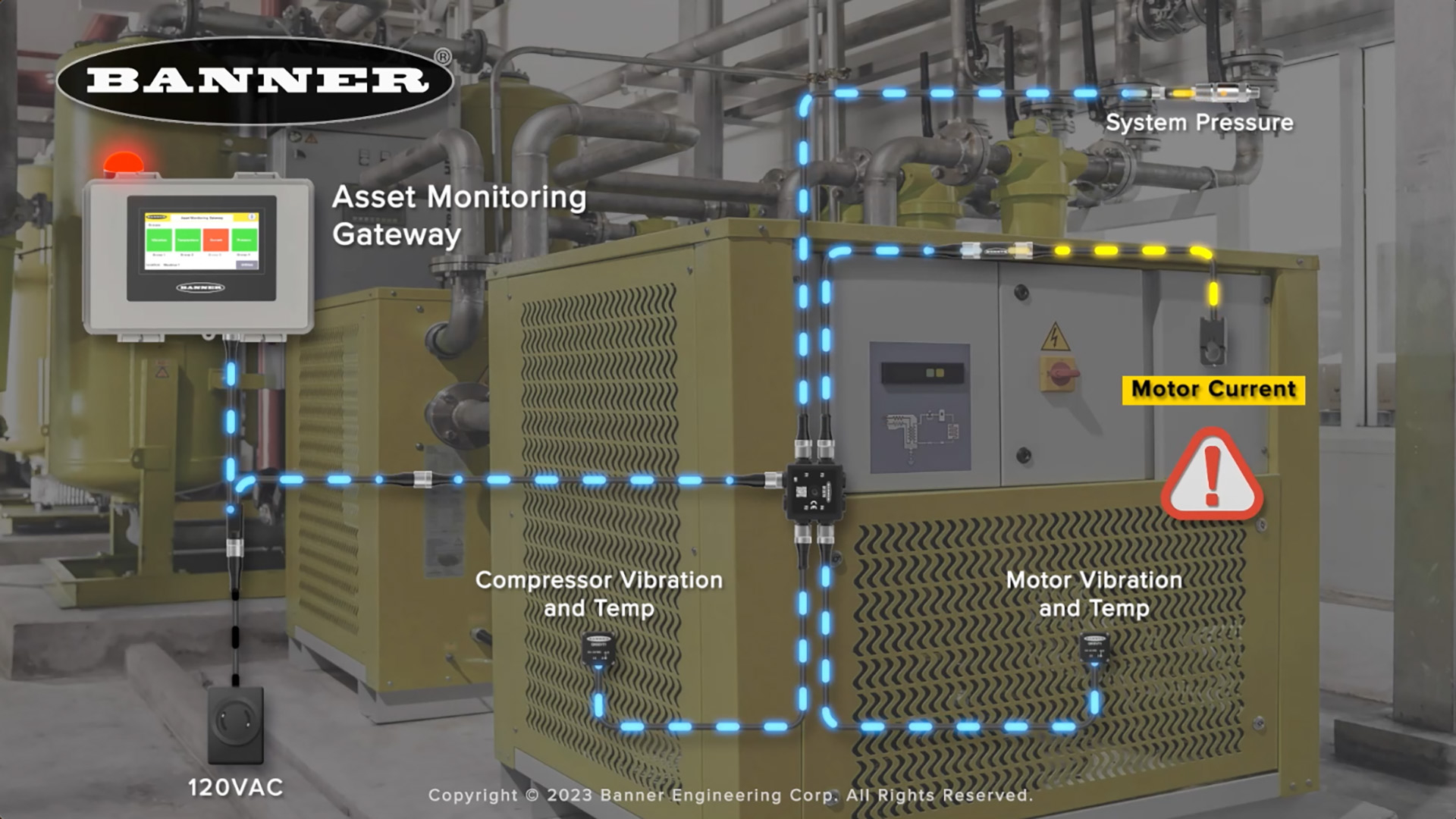

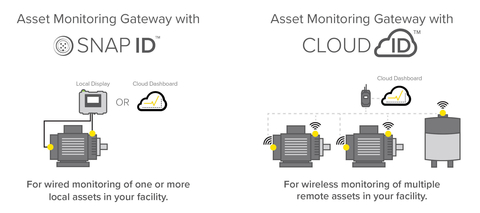

The core of each system is a compact, centralized device called a monitoring gateway, which is placed on or near machine assets. The Asset Monitoring Gateway with SNAP ID has a touchscreen display for local viewing of machine performance, can connect via wires up to 20 sensors, and monitors one or multiple nearby pieces of equipment. Facilities with many pieces of equipment can use the Asset Monitoring Gateway with BANNER CLOUD ID, which can receive data from up to 40 wireless sensor nodes spread across many assets.

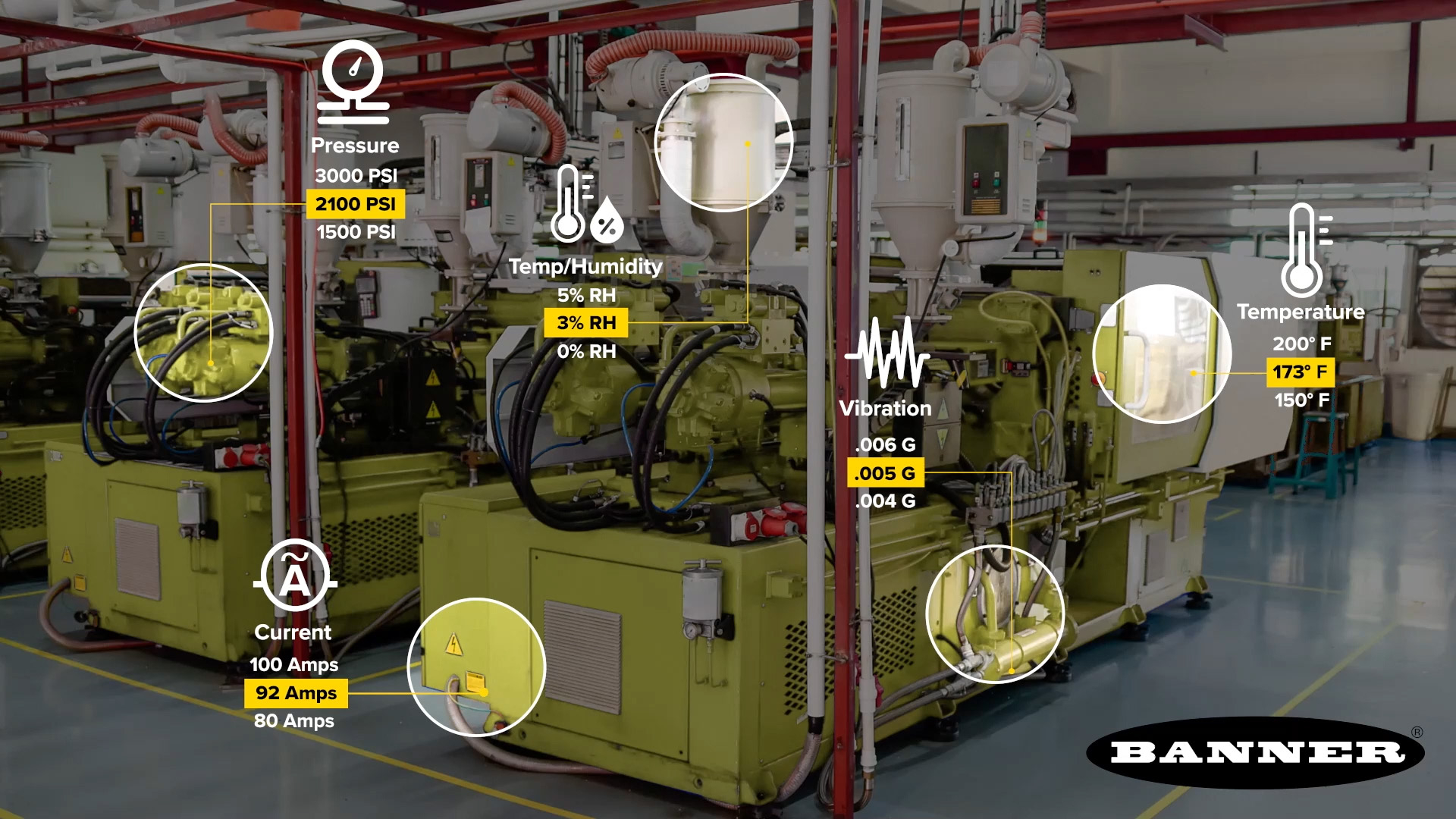

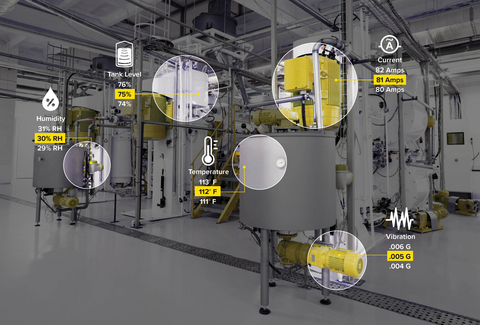

Each system is designed to be deployed quickly without programming and has automatic recognition of compatible sensors or sensor nodes. These sensors and sensor nodes are specialized to gather real-time measurements of current, pressure, temperature, vibration, tank level, dew point, or other relevant variables.

“Facility managers may be unaware that a low-cost, simple-to-install monitoring system like this exists,” says Luke Karnas, Sr. Director, Automation Solutions at Banner Engineering. “It’s the quickest and lowest risk path to get into predictive maintenance.”

Both monitoring gateways offer cellular or Ethernet connectivity and streamlined integration with Banner Cloud Data Services (Banner CDS). Customizable dashboards in Banner CDS provide global visibility into machine health and performance and deliver condition-based text and email alerts.

To help users customize a monitoring solution package, Banner provides a web-based Bundle Builder tool. This tool allows users to select a monitoring gateway, wired sensors or wireless sensor nodes, compatible mounting brackets, and connectivity components. In addition, application engineers are available to help customers build their solution via phone or chat.

Application Examples

The following are just a few of the many applications for a Banner monitoring solution:

- Application: Motor and gearbox monitoring

- Application: Air filter monitoring

- Application: Hydraulic power-unit monitoring

Banner Engineering manufactures industrial automation products that include sensors, smart IIoT and industrial wireless products, LED lights and indicators, machine safety equipment, as well as barcode scanners and machine vision devices. These products help produce the cars we drive, the food we eat, the medicine we take, and many of the things we touch every day. Headquartered in Minneapolis since 1966, Banner is an industry leader with more than 10,000 active products, operations on five continents, and a worldwide team of over 5,500 employees. Every 2 seconds a Banner product is installed somewhere in the world. Online at BannerEngineering.com

Banner Cloud Data Services, Asset Monitoring Gateway with SNAP ID, and Asset Monitoring Gateway with CLOUD ID are trademarks or registered trademarks of Banner Engineering Corp.